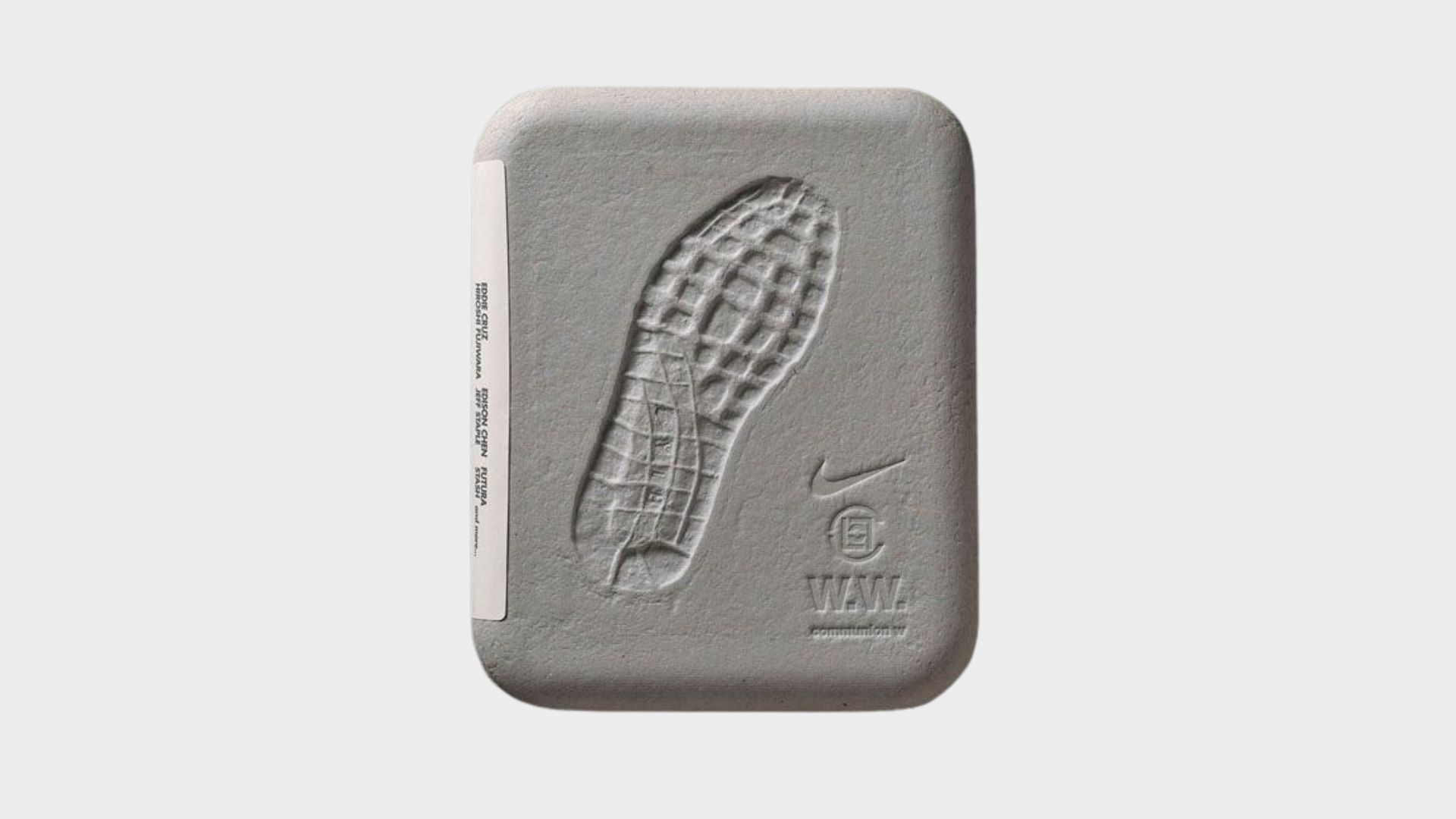

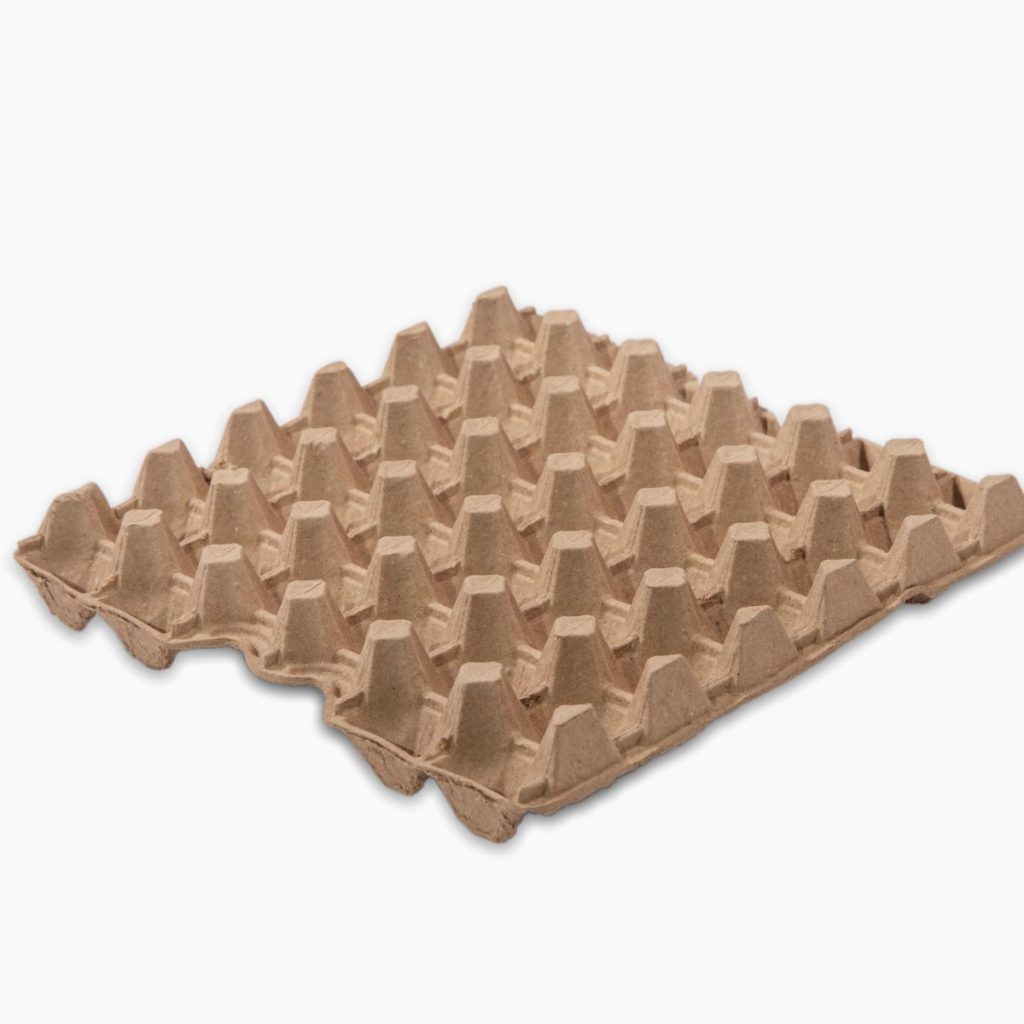

Molded Pulp Packaging - Molded pulp or molded fiber (also spelled as moulded pulp or moulded fibre) is a packaging material, that is typically made from recycled paperboard and/or newsprint. When the pulp parts are formed, they need to release from the forming and. Molded pulp packaging is made by combining bagasse with water and a binder to create a pulp slurry. The slurry is then poured into a mold where it is cured under high heat and pressure and then. This comprehensive guide explores the benefits and applications of molded pulp packaging, focusing on keywords like bagasse and molded fiber, molded pulp trays, and paper pulp. Unlike traditional folded cardboard boxes, molded pulp packaging has rounded corners and complex three dimensional shapes.

This comprehensive guide explores the benefits and applications of molded pulp packaging, focusing on keywords like bagasse and molded fiber, molded pulp trays, and paper pulp. Unlike traditional folded cardboard boxes, molded pulp packaging has rounded corners and complex three dimensional shapes. The slurry is then poured into a mold where it is cured under high heat and pressure and then. Molded pulp packaging is made by combining bagasse with water and a binder to create a pulp slurry. When the pulp parts are formed, they need to release from the forming and. Molded pulp or molded fiber (also spelled as moulded pulp or moulded fibre) is a packaging material, that is typically made from recycled paperboard and/or newsprint.

Unlike traditional folded cardboard boxes, molded pulp packaging has rounded corners and complex three dimensional shapes. Molded pulp packaging is made by combining bagasse with water and a binder to create a pulp slurry. Molded pulp or molded fiber (also spelled as moulded pulp or moulded fibre) is a packaging material, that is typically made from recycled paperboard and/or newsprint. This comprehensive guide explores the benefits and applications of molded pulp packaging, focusing on keywords like bagasse and molded fiber, molded pulp trays, and paper pulp. When the pulp parts are formed, they need to release from the forming and. The slurry is then poured into a mold where it is cured under high heat and pressure and then.

Molded pulp an alternative to conventional packaging DesignWanted

The slurry is then poured into a mold where it is cured under high heat and pressure and then. This comprehensive guide explores the benefits and applications of molded pulp packaging, focusing on keywords like bagasse and molded fiber, molded pulp trays, and paper pulp. Molded pulp or molded fiber (also spelled as moulded pulp or moulded fibre) is a.

MOLDED PULP Interbrands Packaging

Unlike traditional folded cardboard boxes, molded pulp packaging has rounded corners and complex three dimensional shapes. This comprehensive guide explores the benefits and applications of molded pulp packaging, focusing on keywords like bagasse and molded fiber, molded pulp trays, and paper pulp. The slurry is then poured into a mold where it is cured under high heat and pressure and.

Molded Fiber Pulp Packaging Market will Witness a Booming CAGR of 5.1

Molded pulp or molded fiber (also spelled as moulded pulp or moulded fibre) is a packaging material, that is typically made from recycled paperboard and/or newsprint. Unlike traditional folded cardboard boxes, molded pulp packaging has rounded corners and complex three dimensional shapes. Molded pulp packaging is made by combining bagasse with water and a binder to create a pulp slurry..

RoHS Dry Press Molded Pulp Conventional Industrial Packaging With Clean

The slurry is then poured into a mold where it is cured under high heat and pressure and then. When the pulp parts are formed, they need to release from the forming and. Molded pulp or molded fiber (also spelled as moulded pulp or moulded fibre) is a packaging material, that is typically made from recycled paperboard and/or newsprint. This.

Molded Pulp Packaging Market Rising Tremendously with Better Market

When the pulp parts are formed, they need to release from the forming and. The slurry is then poured into a mold where it is cured under high heat and pressure and then. This comprehensive guide explores the benefits and applications of molded pulp packaging, focusing on keywords like bagasse and molded fiber, molded pulp trays, and paper pulp. Molded.

Paper Pulp Moulded Packaging at Rs 5/piece Bhatasan Gandhinagar

Unlike traditional folded cardboard boxes, molded pulp packaging has rounded corners and complex three dimensional shapes. When the pulp parts are formed, they need to release from the forming and. Molded pulp or molded fiber (also spelled as moulded pulp or moulded fibre) is a packaging material, that is typically made from recycled paperboard and/or newsprint. The slurry is then.

Industrial Molded Pulp Interbrands Packaging Package Solutions

When the pulp parts are formed, they need to release from the forming and. The slurry is then poured into a mold where it is cured under high heat and pressure and then. Unlike traditional folded cardboard boxes, molded pulp packaging has rounded corners and complex three dimensional shapes. Molded pulp or molded fiber (also spelled as moulded pulp or.

MOULDED PULP PACKAGING Hants

Molded pulp or molded fiber (also spelled as moulded pulp or moulded fibre) is a packaging material, that is typically made from recycled paperboard and/or newsprint. Molded pulp packaging is made by combining bagasse with water and a binder to create a pulp slurry. When the pulp parts are formed, they need to release from the forming and. Unlike traditional.

What is Molded Pulp Sustainable Packaging Industries

Molded pulp packaging is made by combining bagasse with water and a binder to create a pulp slurry. The slurry is then poured into a mold where it is cured under high heat and pressure and then. Molded pulp or molded fiber (also spelled as moulded pulp or moulded fibre) is a packaging material, that is typically made from recycled.

Industrial Molded Pulp Interbrands Packaging Package Solutions

Molded pulp packaging is made by combining bagasse with water and a binder to create a pulp slurry. When the pulp parts are formed, they need to release from the forming and. Unlike traditional folded cardboard boxes, molded pulp packaging has rounded corners and complex three dimensional shapes. The slurry is then poured into a mold where it is cured.

Molded Pulp Or Molded Fiber (Also Spelled As Moulded Pulp Or Moulded Fibre) Is A Packaging Material, That Is Typically Made From Recycled Paperboard And/Or Newsprint.

The slurry is then poured into a mold where it is cured under high heat and pressure and then. When the pulp parts are formed, they need to release from the forming and. This comprehensive guide explores the benefits and applications of molded pulp packaging, focusing on keywords like bagasse and molded fiber, molded pulp trays, and paper pulp. Unlike traditional folded cardboard boxes, molded pulp packaging has rounded corners and complex three dimensional shapes.